Engineering CapabilitiesI’ve always been a “hands-on” person which helped me comprehend technical subjects as I learned them. My career started in CNC machine tools, Aerospace, and defense as a Manufacturing Engineer and an FMS Applications Engineer. When that plant closed I worked on a large-scale Toyota Production Systems (Lean) implementation in an engine factory producing 16,000 engines per day. The technical knowledge and experience, combined with a PASSION for Lean Six Sigma gives me a broad skills base to assist my clients. With extensive materials, processes, machine tool, and systems knowledge, I can assist on many technical challenges with product & process development. |

||

|

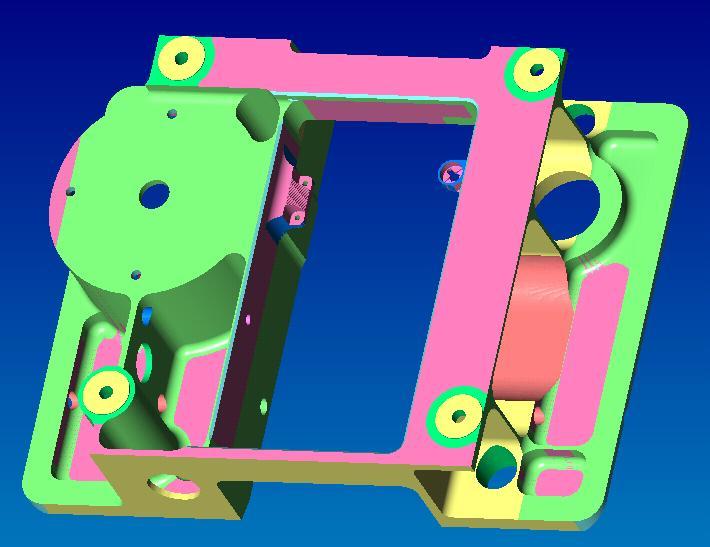

CNC 5-Axis FMS Click photo for more info |

Product / Process Development |

Photo Gallery Click photo for more info |

|

|

||

|

|

Visual Examples of Work This is a small sample of work due to ITAR regulations and the proprietary nature of business. |

Lean Six Sigma Black Belt, Manufacturing Engineer, Operations.

Currently Seeking New Consulting & Contracting Opportunities!

Steve Heidtke, CPIM, M.Ed.